Hygienic Design Enclosures in Food & Beverage Manufacturing

Anyone who works in support of the electrical equipment used by food and beverage manufacturing facilities will know that, however enticing the product, these factories can be hostile places for mechanical drives and electrical components. Raw ingredients, such as sugars and yeast, can play havoc with the output and lifespan of expensive machinery.

An enclosure creates a protective environment for sensitive electrical components, while also protecting operatives from contact with the electrical circuitry.

However, in tightly regulated environments such as those required for food preparation, the quality and design of these enclosures is exceptionally important.

On food production lines, enclosures must not just protect the electrical components, they must also meet stringent cleanliness and hygiene standards which have been laid down to protect public health.

This type of enclosure is commonly referred to as a 'hygienic design' (HD) enclosure.

The hygiene regulations that govern our food and beverage production are necessarily strict. Any breaches of the regulations can be hugely expensive for a manufacturer, involving product recalls and production downtime, as well as lead to substantial reputational damage and possibly even fines.

However, while there is an obligation for these standards to be met, the directives that bind the industry do not advise companies how to judge whether their electrical enclosures are suitable to be placed within such a sensitive environment.

The lack of standardised, recognised guidance means that systems and mechanical engineers, as well as the factory management team, must use their own judgement as to which type of HD enclosure should be used.

Their choices often involve understanding small and (sometimes) nuanced details around design features including:

- IP ratings

- Materials and surfaces that allow for easy cleaning and corrosion-resistant etc

- Robust connection systems, such as seals and seams

- Angles and corners designed for easy washdown while not collecting contaminants

- Protection of the circuitry from water ingress and contaminants

Hygienic Design

Most enclosures (whatever the application) are selected primarily for their IP rating.

Unfortunately, it’s a misconception that a high IP rating would be the most important feature of an enclosure, particularly for food and beverage manufacturing plants.

Industrial wall-mounted enclosures and standard enclosures for machines and plants are typically not designed for either fast and thorough cleaning, or prolonged exposure to water.

In fact, standard enclosure design makes deep cleaning almost impossible, thanks to features such as hinges, door locks, cable glands and plinths, all of which have areas where foodstuff can congregate, which in turn will become a breeding ground for microbes.

External Design & Construction

Hygienic design, as the name implies, allows for the easy, deep cleaning of an enclosure. For example, by using stainless steel as the construction material for the external parts, the enclosure can offer a high resistance to chemicals, cleaning agents, and disinfectants.

Any dead spaces, undercuts, or joints without radius, should have been removed because these can allow product residue to accumulate.

Equally there should be no recesses, such as uncovered screw threads, screw heads with internal hexagons (Allen screws), or Torx screws. Corners and joints must be smooth, gapless, and cleanly rounded.

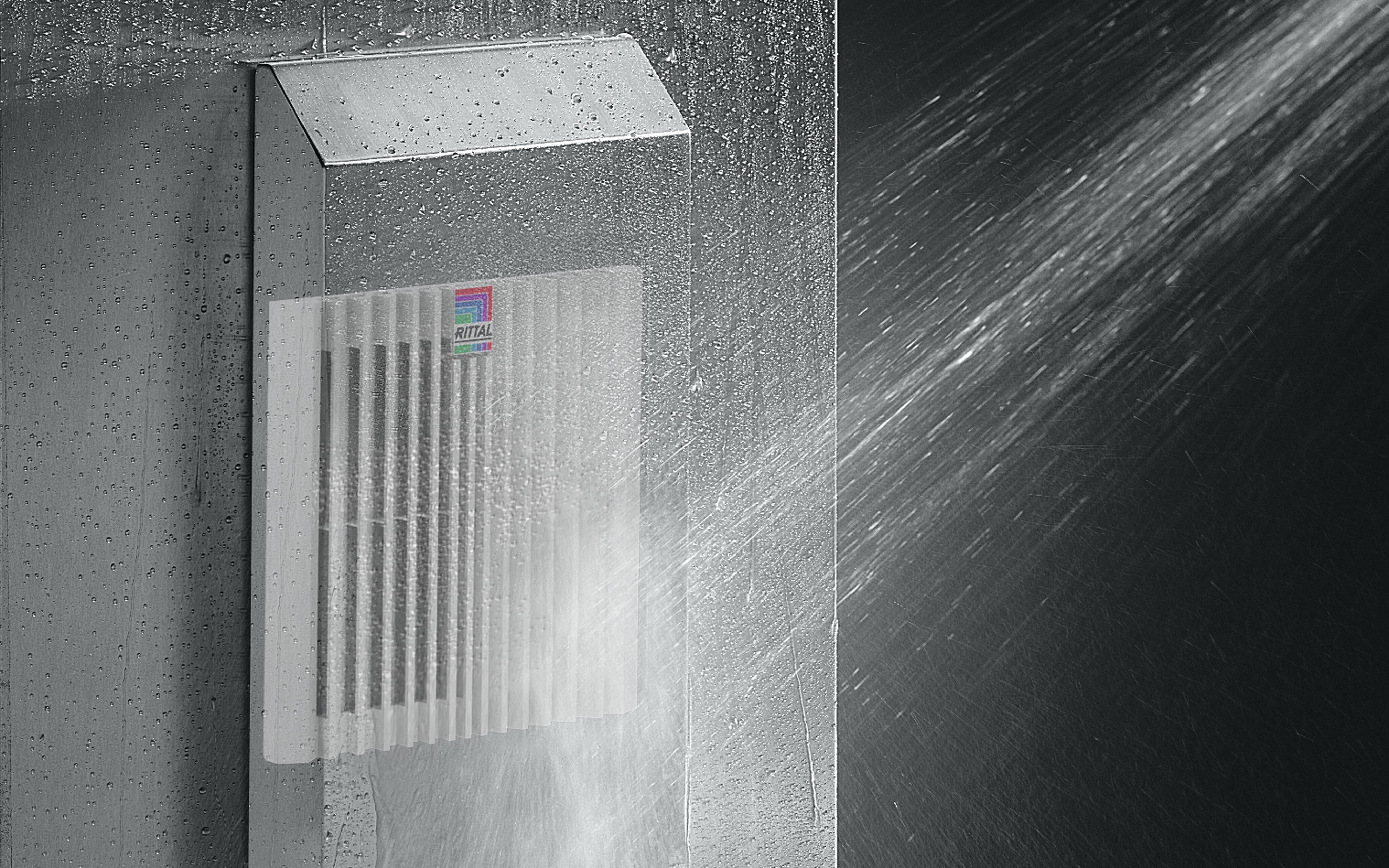

The high-intensity jets of hot water used for cleaning need to be able to run-off the surfaces of the enclosures in the so-called spray and wet zones, which means providing appropriately angled drain slopes. A sloping roof to the enclosure doesn’t just allow water run-off, it allows for easy inspection - and prevents anyone putting anything on top of it!

And there should be other, smaller but just as vital adaptations. For example, wall brackets that are round and smooth, and doors with sloping upper edges to prevent water collecting on them which could erode their seals.

Finally, the cable glands should have interior threads so the outer surface is smooth.

Door Seals

Door seals on standard enclosures are designed to keep out wind and driving rain, not high-pressure hot water.

Their seals can only withstand so much cleaning before they breakdown which will give water access into the enclosure. Water and electrical components clearly do not mix, so any breakdown of a door seal increases the chances of an electrical short circuit and a breakdown in the production line.

Also, when the seals breakdown the jets of water used for cleaning can force foodstuff into the enclosure and this then becomes a breeding ground for bacteria.

Summary

Electrical enclosures are a fundamental part of the production line but may be considered as just ‘metal boxes’.

That would be a major error of judgement. Enclosures house critical electrical infrastructure; they protect thousands of pounds worth of equipment and ensure that production lines keep running. They also keep staff members safe.

Our stainless steel Rittal Hygienic Design (HD) enclosures meet these tough hygienic requirements in full. Our entire range has been meticulously designed to meet the requirements, regulations and guidelines of the food and beverage industry.

These enclosures meet the IP66 protection category in accordance with IEC 60 529, as well as the NEMA 4X protection class. This means they can be cleaned with a high-pressure cleaner without any danger of water ingress.

Their door seals are made of silicone instead of polyurethane (PU foam). Silicone has greater resistant to all kinds of detergents and is dyed blue which makes it identifiable as a “foreign object” in the event of any mechanical damage. In addition, one-piece gaskets are securely fitted on the insides of the doors/outside of the panels to guarantee an unbroken seal.

Don’t forget to watch the Rittal unBoxed podcast episode on YouTube which includes a deeper dive into Rittal's support for the food and beverage industry.