Make wire processing ten times faster with Rittal’s Wire Terminal WT C

Rittal’s Wire Terminal WT C5 and C10 machines offer fully automatic wiring processes that go one step further. The innovative design of the WT machines allows for wire processing that is ten times faster than if done manually. Due to the modular system design and flexible package options, panel builders and switchgear manufacturers now have a future-proofed automation solution. The WT machine can be adapted from a smaller version and expanded as your business grows to include additional hardware and software. The WT machine provides users with cross-process solutions that include networking, electrical engineering, and production processes.

Manual wiring in the panel building and switchgear manufacturing industry is a time-consuming task that involves on average 50% more processing time. Within the panel building industry, businesses are asking how they can decrease their assembly and wiring processes, all while reducing the costs and man-hours involved, at the same time as still achieving the same high-quality results. Another question is how can machine operations and production processes be made simpler. Finally, planning and consideration needs to go into the plant machinery and construction as this will lay the foundation for technological advancements that must be able to meet industry demands in ten years’ time.

Rittal has the solution with its new, fully automated wire processing machines: the Wire Terminal WT C5 and C10. The wire-processing machines allow for individual wire-cutting and printing (black, white, and light blue) and picking, to be assembled ten times faster than by hand. The automated wire-processing machines also provides core benefits in a variety of combinations including the different wire output methods and support for downstream, digitally consistent, and automated processes such as labeling, sorting, and transportation.

The technical basis for the many different functions of the Wire Terminal WT C5 and C10, is the adaptable and expandable modular system that includes both the hardware and software components, as the system is scalable and flexible to meet your business’s needs, it provides the ideal platform to meet future industry requirements. This is supported by an achievable return on investment period of 2.5 years based on a minimum of 300 enclosures per year.

Flexible configuration at every stage

The Wire Terminal WT is available in two different versions and offers flexibility at every stage of the configuration process. As an entry-level wire processing solution, Rittal offers the WT C5 wire processing machine, with five vibratory bowl feeders for wire-end ferrules and wire-end treatment, the WT C5 also features a cross-section ranging from 0.5 to 2.5 mm², the product also cuts to length, labels, and crimps. The WT C10 wire processing machine has ten vibratory bowl feeders for wire-end ferrules with wire cross-sections of up to 6 mm² as a default setting. Both wire-processing machines have the capability to be adapted and expanded to offer full functionality in their respective wire applications.

Wiring automation made simple

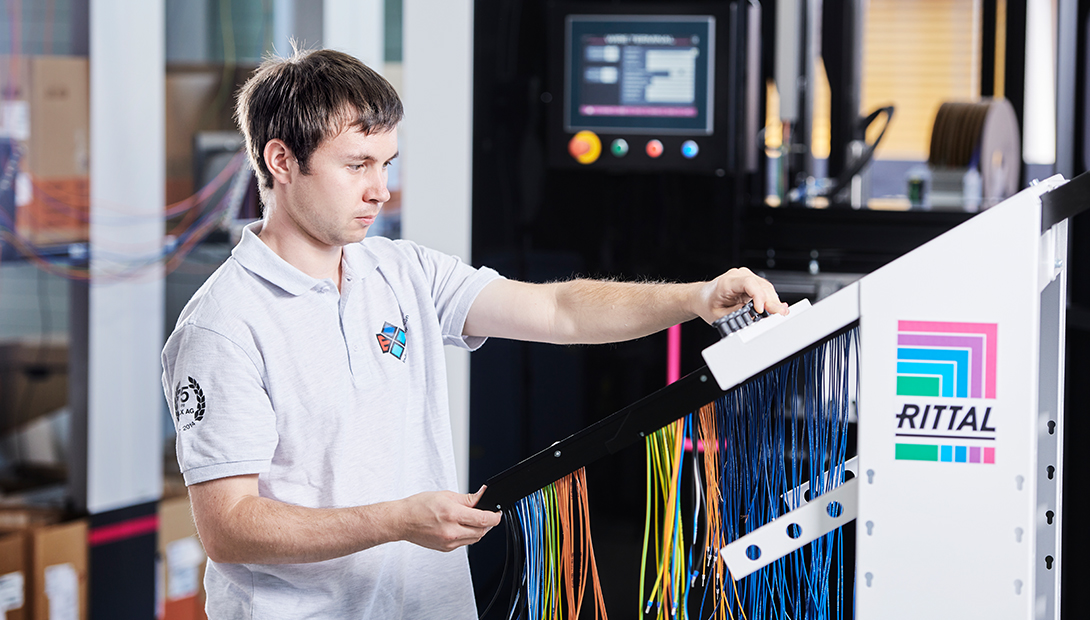

The Wire Terminal WT machines are fully automated and can be easily operated via a 24” inch display screen, the display screen provides many benefits such as when feeding and outputting the wires. Safe wire feeding and a simple fast changeover process to new wires can be achieved thanks to a new type of wire feeding system that features three feed blocks that can accommodate up to 36 wires and 12 wire types per feed block. This quick-change system allows the feed blocks to be set up and flexibly changed as per the build specification. An RFID transponder automatically secures the wire feed, making it easy and straightforward to change over the wires completely.

Reliability at every stage of the wire processing

Reliability at every stage of the wire processing

The WT C10 offers maximum flexibility thanks to up to ten vibratory bowl feeders during the process of safely inputting the loose wire end ferrules, supported by a straightforward refill process, the WT C10 makes wire end treatment a simple and efficient process. With that in mind, the new technological developments of the WT C10 crimper allow for the efficient processing of wire end ferrule lengths, ranging from 8 – 18mm. Using the new crimper, you can choose between partial and stripped wiring up to 20mm. This new crimper uses servomotor technology to ensure high-level consistency during wire processing.

A third wire output method

Dependent on the requirements of the enclosure build or specification the wires can be dispensed from the machine in three different ways: through ejection, by a rail system, or via a chain bundler. As Rittal’s WT C10 can hold up to 2100 wires at any given time the need for wire sorting is unnecessary as the pre-assembled wires are produced in wire rails as standard. This enables the lined-up wires to be processed quickly and efficiently, this in conjunction with the wire cart trolley improves the process of order picking during the build and dispatch process.

Using the WT C10 machine, chain bundles can also be produced to make the wiring process even more efficient; wires are then subsequently arranged in the chosen order. This allows businesses to be flexible with the services that they can offer to prospective customers. This service offering is only possible thanks to the Wire Terminal three adjustable output options that can be implemented. Along with integration with “Eplan smart wiring” software. Eplan’s smart wiring application supports the wiring technician by providing all the necessary information in a digital and or 3D format. Along with providing digital engineering data and always up-to-date project comparisons. This in turn adds additional value at every stage of the enclosure wiring process.

To find out more about Rittal's automation systems, follow the link below:

To find out more about Rittal's Wire Terminal WT C machines, follow the link: