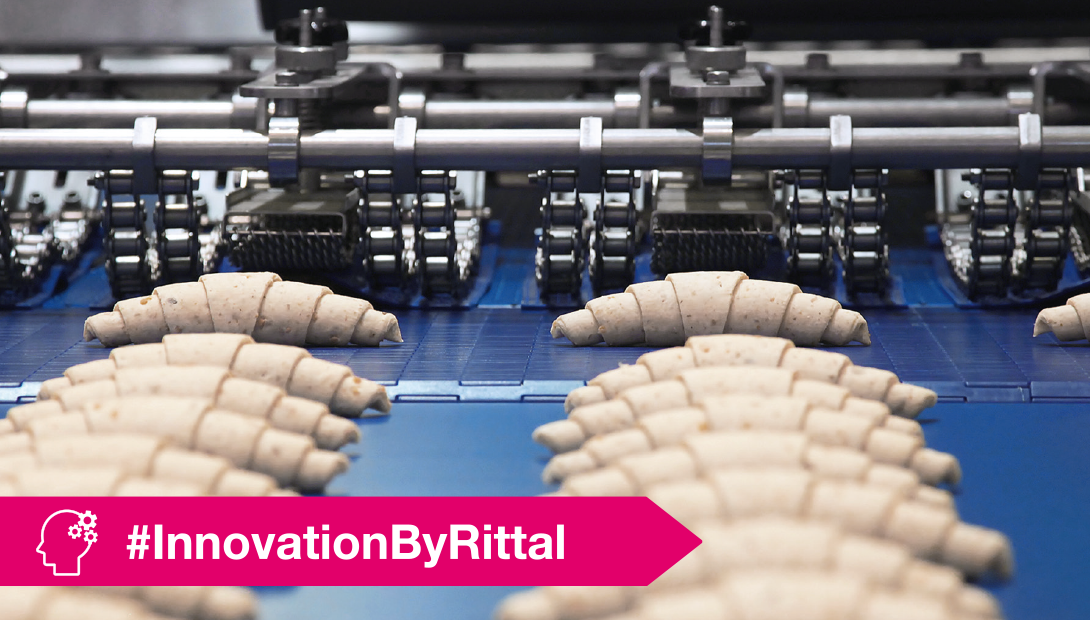

Rittal's next generation cooling technology reducing energy consumption for bakery ovens.

The UK Food and Beverage sector is one of many industries that is having to rapidly adjust to consumer needs and behaviors.

In recent years, the demand for food and drink products has heightened and as a result such facilities are now having to offer round-the-clock production, to support both modern lifestyles and the use of online ordering, such as click and collect. This in turn is having a major impact on factory infrastructure.

Allied Bakeries, a household name thanks to brands such as Kingsmill and Allinson is no different. In 2019, Rittal UK was approached by Rob Shaw, Site Controls Engineer for Allied Bakeries’ Walthamstow facility, which produces circa 1.5 million loaves per week.

The company was performing a continuous improvement appraisal on the plant tunnel oven, which bakes bread at a rate of 10,000 loaves per hour.

Cooling the electrical equipment required to run any industrial production line is vital to ensure its continued optimum operation. Allied Bakeries was already protecting its equipment with Rittal’s ‘Blue e’ cooling units. It's engineers were keen to explore if an upgrade to this equipment, would reduce the energy and carbon footprint of the site, whilst maintaining the high level of protection required by the oven’s controlling equipment.

The Rittal team undertook a fact-finding tour of the Walthamstow site to understand the wider processes, location and environmental conditions in which the electrical equipment has to operate.

Blue e+’ Cooling Units as an Innovative Solution

Based on their initial consultation and after further discussions with Allied Bakeries Engineering Team, the Rittal team was able to confirm that the technology-leading ‘Blue e+’ Cooling Units would fit the criteria. These new generation cooling units use state-of-the-art technologies, to deliver industry-leading climate control within a factory environment. In addition, the hybrid cooling technology provides on average a 75 percent lower energy consumption than previous generation ‘Blue e’ units. This represents a quantum leap forward for cooling systems and is a major incentive for food and beverage production facilities, seeking to minimize steep rises in energy prices and reduce there carbon footprint.

In addition, Blue e+ unlocks the potential of Industry 4.0 through a remote monitoring capability when used in conjunction with Rittal’s IoT Adaptor. This means that Allied Bakeries’ Engineers now have constant access to the cooling system’s performance data, as well as early warning of any issues before they escalate and cause electrical equipment failure and line stoppages.

To keep up to date on all the latest cooling topics over the next few months register your interest below:

To learn more about Blue e+ remote monitoring solutions and the IoT climate control capabilities, follow the link below:

To learn more about how Nestlé have taken part in energy saving research with Blue E+ technology, take a look at this latest blog post: