Rittal's Haiger plant Named "Factory of the Year 2025" - A Benchmark in Digital Manufacturing

Introduction

Rittal's state-of-the-art manufacturing facility in Haiger, Germany, has been awarded the prestigious title of "Factory of the Year 2025" by a jury of panelists from management consultancy firm Kearney and trade magazine "Produktion". One of the highest awards for more than 30 years, it has only been given to the best factories in the world, and the feedback we've received highlights how the jury were particularly impressed by the high level of digitalisation and automation throughout the entire works, as well as our focus on the customer during each stage of the manufacturing process.

This recognition highlights the company's commitment to innovation, digitalisation, and customer-centric production - values that resonate strongly with Rittal UK's mission to support British industry with cutting-edge enclosure and automation solutions.

Industry 4.0 in Action

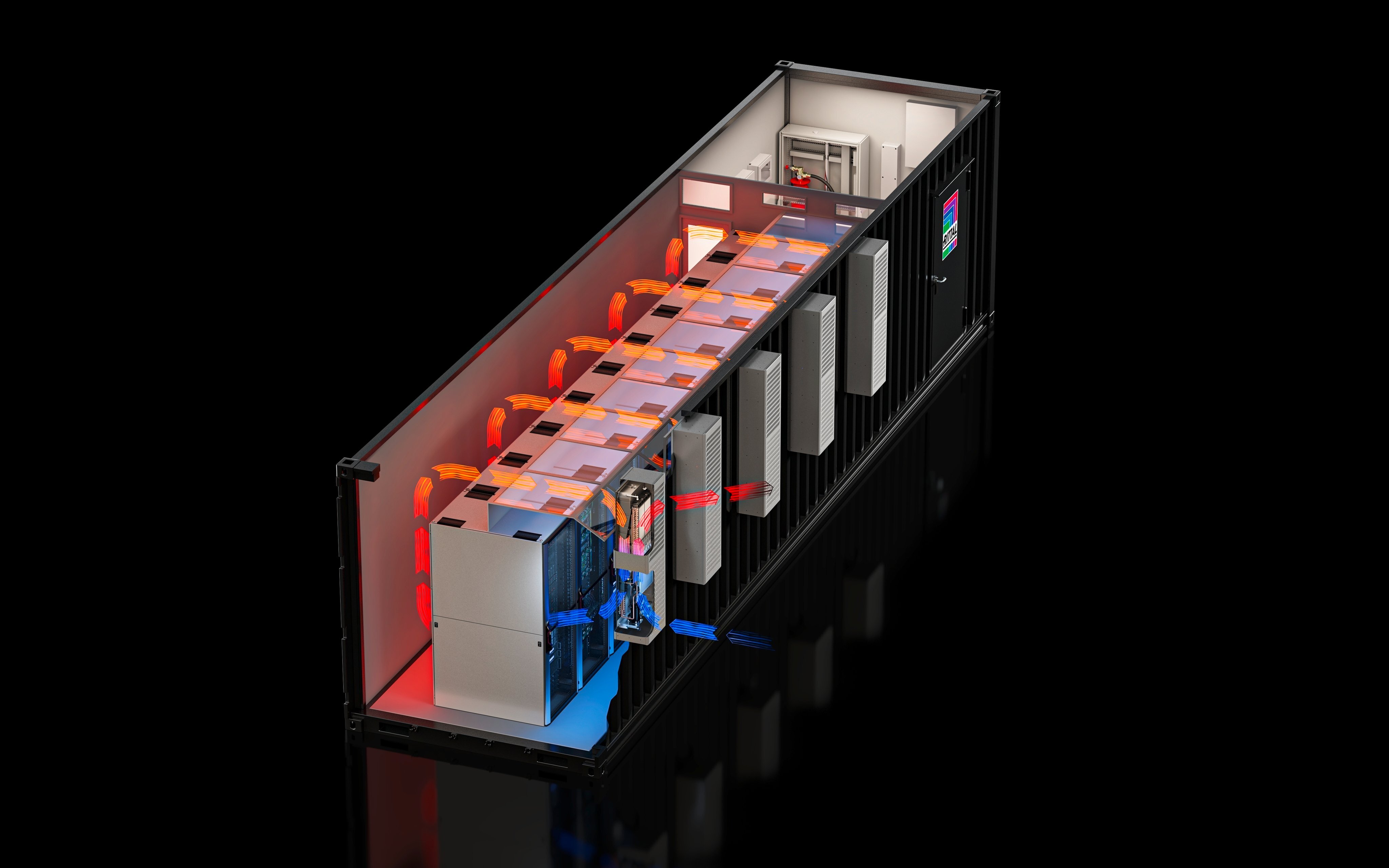

Industry 4.0 is not merely a buzzword, but our reality. From digital twins and AI-driven quality control to QR-based traceability, the factory embodies the principles of Industry 4.0. These technologies are not just theoretical - they're delivering real-world benefits in speed, transparency and reliability.

The Haiger plant stands out for its fully integrated digital processes, producing up to 9,000 compact enclosures daily. With near-perfect planning accuracy of 99.9% and rapid delivery times (24 hours in Germany, and 24-48 hours across Europe), it sets a new standard for smart factory operations and demonstrates the plant's performance.

Customer-Centric Innovation

The jury was particularly impressed by the continuous end-to-end process chain. What does that mean? All steps are mapped digitally - from product configuration and automated factory work processes through to packaging. This allows us to produce series and customised products flexibly, and at any time.

Having only been built a few years ago, many are fascinated by this production facility. "We built many of the systems used in the plant ourselves. We didn't wait for someone to supply the technologies needed for a digitalised factory... we made use of our own expertise and that of our employees, which makes us extremely proud!" explains Jürgen Kromer, Plant Director at Rittal Haiger.

AI testing methods in use

In order to stay ahead of the curve, the team are also promoting AI optimisations in close collaboration with the Rittal Digital Operations department which is headed by Moritz Heide. "Artificial intelligence is already successfully aiding quality control, maintenance, our knowledge management, and software analysis.” Through the use of AI, Rittal, for example, has achieved a remarkable 91 per cent first-time pass rate. The jury was also impressed that time-consuming rework was now largely a thing of the past.

“Because our data is available in high quality across the entire value chain, we can use AI in a focused way,” Mr. Heide says: “In engineering, for instance, we are helping our customers become much faster with AI-supported software solutions from our sister company Eplan. At the factory, we minimise errors using AI tools. The highest data quality and availability throughout the entire process is the standard our customers can expect.”

Commitment to the location

“Through its victory in the main category, Rittal has won the highest award that a production company in Europe can receive,” says Professor Friedhelm Loh, owner and CEO of the Friedhelm Loh Group, of which Rittal is the largest member: “We are very grateful for the jury’s decision to award us this prize. I would also like to thank the Rittal team for making this possible. The plant represents a commitment to Germany and Europe as a production location. It safeguards jobs for employees and their families in our region, and that makes us very proud.”

The plant's digitalisation journey is rooted in customer value. As Jürgen Kromer, Plant Director, explains: "Efficiency is important, but transparency, quality and availability are what truly benefit our customers."

"Our factory shows what is possible when digitalisation is consistently thought through and implemented" says Jürgen Kromer, Plant Director at Rittal Haiger.